No. 1 The Safest HVLS Fan Manufacturer in Canton China

“We create natural wind for your working plants and large spaces – more comfortable, more energy-saving, higher working efficiency”

Explore Our Services

01 Design Solution

02 Installation

03 Maintainence

Installation Projects

Latest Posts

About MPFANS

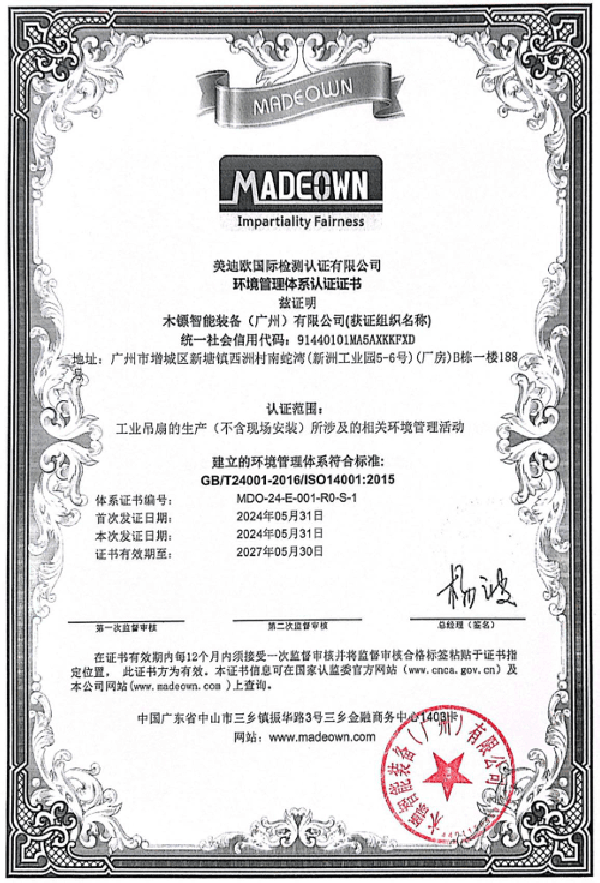

Move Point is the top HVLS fan manufacturer in Canton, China. Our fans are known for the experience, safety, and performance. In 2018, the founders established Move-Point Intelligent Equipment (Guangzhou) Co., Ltd. It spans over 6,000 square meters. Our factory integrates R&D, manufacturing, and sales.

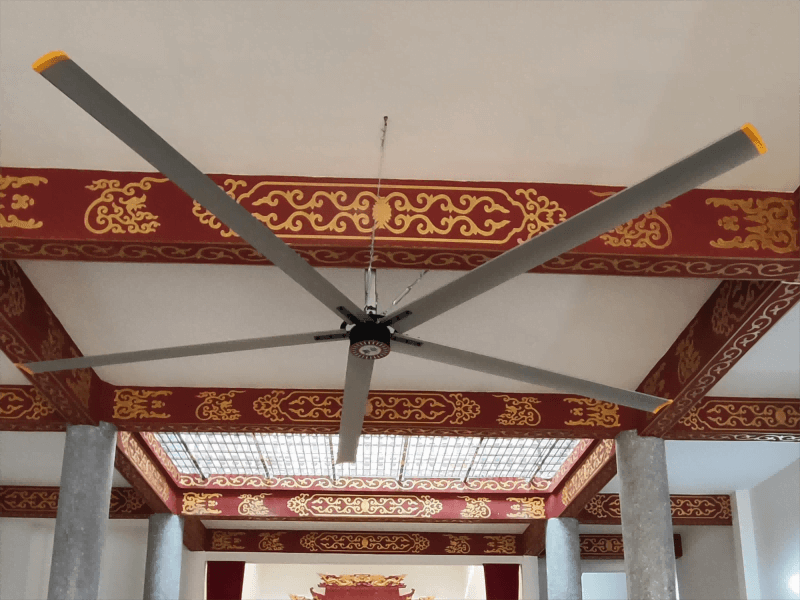

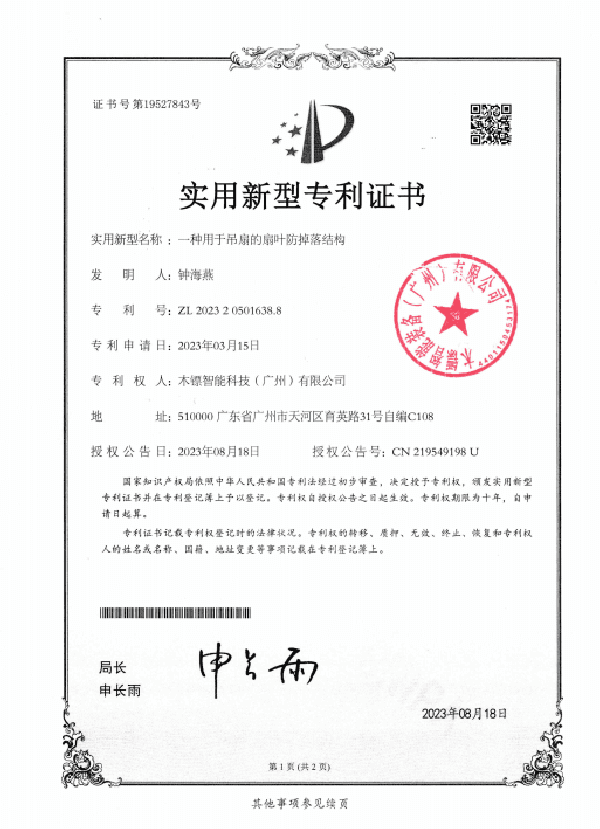

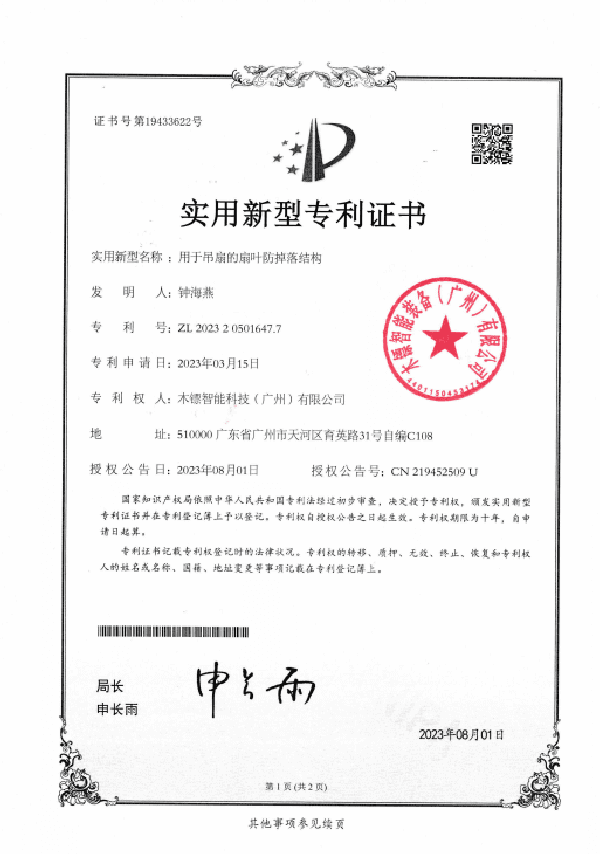

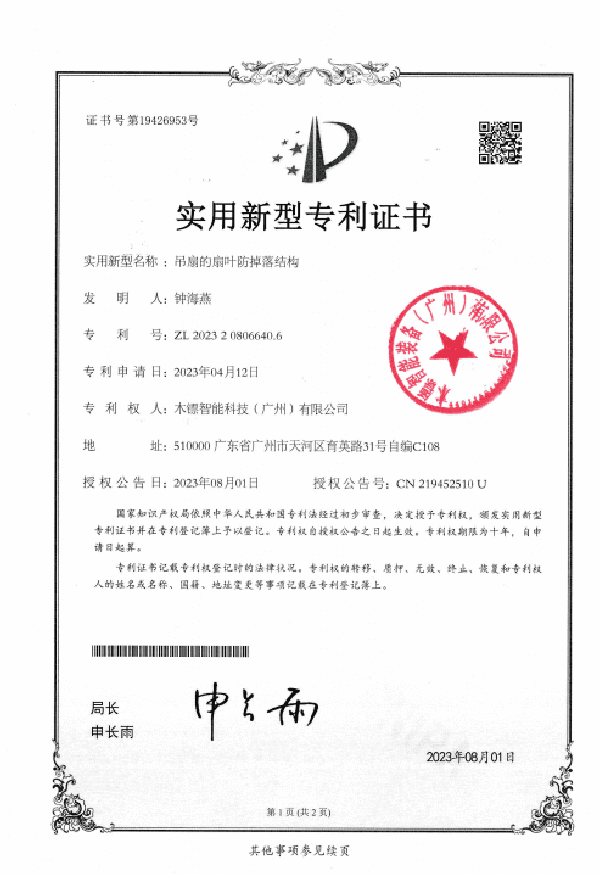

We only focus on one thing: the large HVLS (High Volume Low Speed) ceiling fans, also known as big industrial fans. We use German Lenze motors and PMSM for power. Our fan blades are made from 6061 aero-grade aluminum-magnesium alloy. Moreover, we hold exclusive patents for our safety components.

Safety is a key advantage of Move Point HVLS fans. We use advanced engineering and strong materials to meet strict safety standards.

Feel free to consult us or visit our company. Our goal is to make the safest HVLS fans in China.

Our Certificates

FREQUENTLY ASKED QUESTIONS

What is HVLS fans? What is the full form of HVLS?

The full form of HVLS is High Volume Low-Speed.

The fans size are much bigger than normal fans. It moves slowly just like below, it is widely used for industrial working shop, and nowadays, more and more people use it for the playground, temple, hall, etc. Many large spaces can be installed with this kind fan for better ventilation and cooling:

What are the benefits of HVLS fans?

The Benefits of HVLS Fans: Why Factories Prefer Them for Ventilation

Cost and Energy Savings

HVLS fans save money and energy in large spaces. For instance, a 7.3 m diameter HVLS fan from Move-Point can cover the same area as more than 45 small 0.75 m fans. A 9,000-square-meter plant would need 300 small fans to achieve full coverage. But we only need 9 HVLS industrial energy-saving fans. In four years, an HVLS industrial fan uses 135,000 kWh. Small fans use 1,080,000 kWh. This translates to an energy savings rate of up to 87%, saving 944,500 kWh.

Ease of installation

Another advantage of HVLS fans is their straightforward installation process. HVLS fans circulate large volumes of air in industrial spaces. Smaller fans need many units to do the same job. This reduces the complexity and labor costs associated with the installation.

Enhanced Comfort with Natural Wind

HVLS fans offer enhanced comfort by simulating natural wind. The fans’ gentle breeze makes the factory more comfortable for workers. This is key in large spaces. There, traditional vents struggle to provide consistent airflow. HVLS fans improve air circulation. They help create a more pleasant, productive workplace.

Conclusion

The benefits of HVLS fans are obvious. They save a lot of money and energy. They’re easy to install and convenient. They also improve comfort by simulating natural wind. As factories seek better ventilation, the use of HVLS fans will likely grow.

What are the top 5 spaces to install an HVLS fan?

Top 5 Spaces to Install an HVLS Fan for Optimal Efficiency

Manufacturing Plant

HVLS fans work well in manufacturing plants. They keep a consistent temperature, which is crucial. These fans circulate air, reducing moisture. They ensure employees work in comfort. Additionally, they help in minimizing energy costs by optimizing heating and cooling systems.

Big Warehouse

Warehouses have large spaces and high ceilings. So, they are perfect for HVLS fan installations. These fans keep the air cool in summer and warm in winter. They protect stored goods from temperature damage and make workers more comfortable.

Sports Center

Sports centers, from basketball halls to indoor tennis stadiums, need HVLS fans. They benefit greatly from them. These fans boost air circulation. They create a pleasant atmosphere for athletes and spectators. They help control odor and humidity. Both are key to a healthy indoor sports environment.

Cow Farm

Cow farms need good ventilation. It keeps the cows healthy and productive. HVLS fans move air well. They reduce heat stress on cows and disperse pests, like flies. They help the animals and boost milk production.

Waiting Room for Transportation Station

Transportation stations can get crowded. So, efficient airflow is vital for travelers’ comfort. Installing HVLS fans in waiting rooms improves air circulation. This makes for a better waiting experience. They help maintain a steady temperature. This reduces the need for constant heating or cooling.

How to Choose the Right HVLS Fan for Your Factory?

Introduction

As factory plants seek to ventilate and cool, HVLS fans are popular. They are an effective solution. Selecting the right HVLS fan can be challenging. This guide will explore traditional gear motor fans and modern PMSM fans. It will give tips to help you make an informed choice.

Traditional Gearmotor Fans

Traditional gearmotor fans have been in use for a long time. These fans feature a large motor at the back, which is crucial to their operation. While many people trust this older technology, it has several drawbacks. The gear motor fan is too heavy for plants under 5 meters high. Additionally, it requires regular maintenance, including lubrication. The fans’ power consumption reaches approximately 1500 W for each set.

PMSM Fans: A Modern Alternative

The PMSM fan represents a modern alternative. These fans are lighter, smaller, and more energy-efficient. They use 400 W to 1,300 W. Unlike traditional gear motors, PMSM fans need no maintenance. They are a more cost-effective and convenient option for factory ventilation.

Key Considerations for Choosing an HVLS Fan

Motor Type

When choosing an HVLS fan, the motor type is crucial. Whether you choose a gear motor or a PMSM motor, check the motor’s quality and performance. For gear motors, Germany’s Lenze is a reputable brand. In China, people know Amcling for producing high-quality PMSM motors.

Controller

The fan controller can be either integrated or separate. Most HVLS fan controllers are mature and reliable. There are some variations.

Fan Blade

The material and design of the fan blade also matter. For safety and efficiency, use aerospace-grade 6061 aluminum-magnesium alloy, not regular aluminum. Look for blades with internal reinforcements, like those made by Move-Point.

Safety Components

Ensure that all safety components, including inserters, connectors, and screws, meet high standards. Quality manufacturing materials, such as 1600T heat-forged chassis and No. 45 steel, are indicators of reliable safety measures.

Other Accessories

Other essential accessories include wiring, wave tubes, gaskets, and screws. These parts are key to your HVLS fan’s performance and lifespan.

Conclusion

Choose the right HVLS fan. Check its motor type, controller, blade material, safety parts, and accessories. Focusing on these components will optimize your factory’s ventilation, safety, and energy efficiency.